However, only professionals can operate the screen printers. They apply the ink in layers, which can be time-consuming. This screen printing method has been around for centuries and is still quite effective. And it is more affordable to order screen printed products on large scales so, if you want to make custom t-shirts, this is your best choice. They are limited with color possibilities so you can use them for less detailed works. Share your personality with the world by using a custom vinyl decal on your bicycle, car, motorcycleor that brand new Jeep. Screen Printer: On the other hand, screen printers are better suited for larger pieces. We offer customized decals for every individual need. They have endless color possibilities and combinations and are less cost-effective for large-scale jobs. That is, they do not use any heat or contact but have the link directly bonded with the material.įor high-quality work for smaller designs with many details, digital printers provide many benefits.

Although they do not print white ink, through technological advancements of digital printing, this is rapidly changing.ĭigital printers, especially inkjet printers, are best for intricate, complicated designs as they directly print the graphics onto the surfaces. They cost thousands of dollars, but the results they produce are worth it. They are mainly two in the printing industry, and here is everything you would need to know about them.ĭigital Printers: These are high-end, state-of-the-art machines. It is normal to be in a dilemma about the different types of printers to use to print decals. If you see printed decals on a safety sign and instrument that is resistant to moisture and most wear and tear, they are most likely permanent. Permanent: For labels, stickers, and decals that you plan to keep around for as long as possible, look for permanent adhesives. They hardly leave any residue which makes changing the stickers extremely convenient. Removable: If you intend to change your decals in the future or switch it out often, then go for these adhesives. This is because it uses static electricity as the glue. Static Cling: If you do not want to damage the surfaces underneath, static cling is the best option. The design latches onto the surface without any bumps or bubbles. High Tack: These are a good choice if you want your decals to stay put. We have listed some of the most popular ones there are: Ī recent innovation involves the inclusion of a radio frequency identification (RFID) circuit (chip and antenna) in the paper or film facestock.You may also have to go through different types of adhesives to choose the best ones. Finally, a paper pre-mask can be applied to the top of the vinyl design allowing easy application of multiple letters and shapes. After the patterns are cut, excess vinyl on the sheet is removed in a process called weeding.

#DECAL PRINTING SOFTWARE#

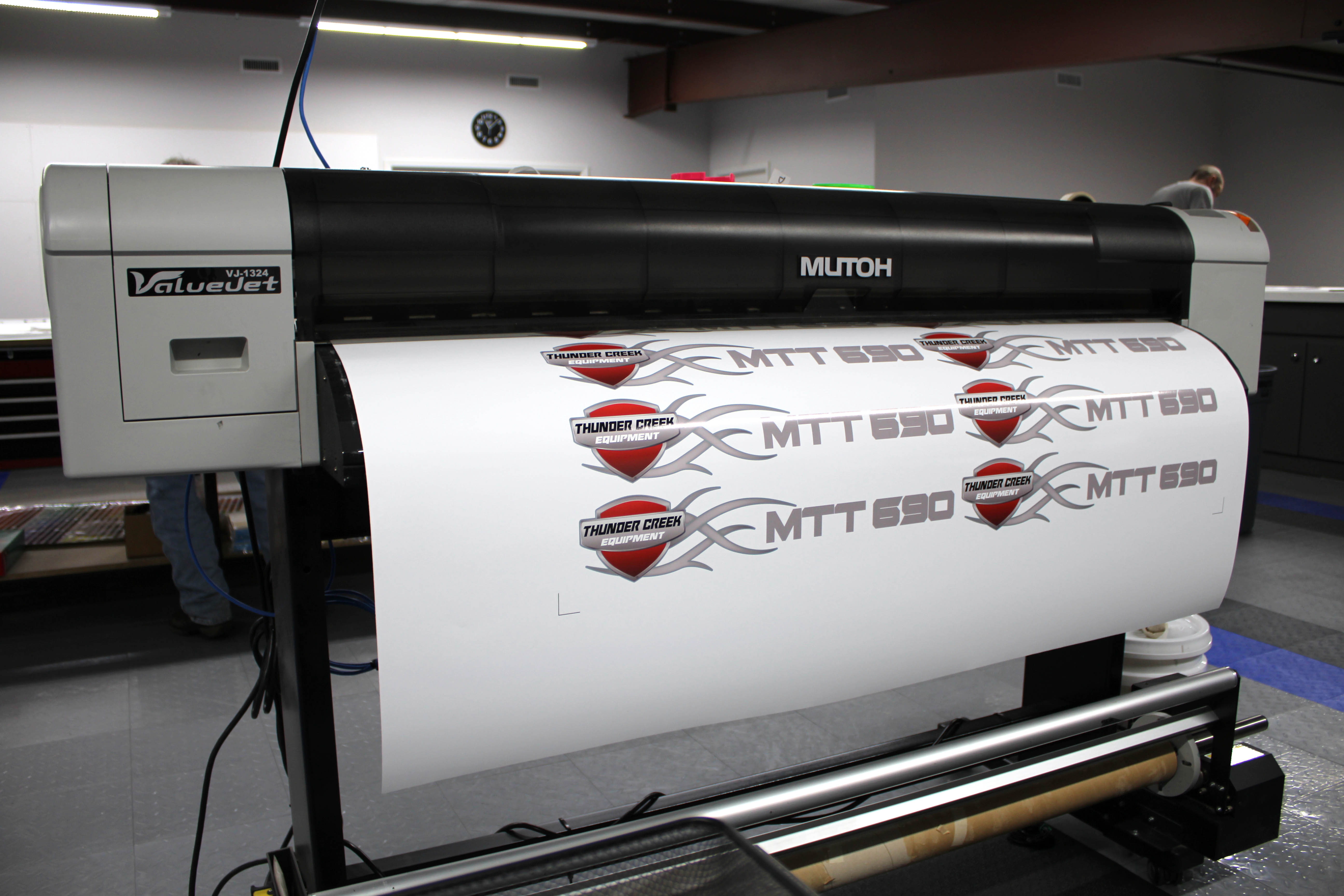

Designs are typically created using specialized computer software and sent to the machines electronically. Vinyl is fed through a cutting plotter or large-format printer/cutter which prints the desired image and cuts out the desired shapes. Mass-production of vinyl decals starts with large rolls of vinyl sheet.

When manufactured out of vinyl the latter is known as a vinyl-cut-decal. Two variations include the traditional water-slide or water-dip, with the artwork screen-printed on water-resistant paper coated with a layer of water-soluble adhesive, and a dry peel-and-stick format using a standard adhesive - which technically is not a decal, as there is no "art transfer", rather an adhesive-backed label known as a sticker. As applied, where only the adhesive-backed artwork remains, affixed to its desired (and appropriate) substrate, temporarily or permanently as designed. Decals are produced, shipped, and stored in this composite state.Ģ. As manufactured, which consists of the artwork printed on the upper side of a paper or film label stock, temporarily affixed by a typically water or heat soluble adhesive to the upper side of a silicone- or other release agent-coated paper or film backing stock. The term "decal" refers to the mass-produced art transfer in two different states:ġ. The technique was invented by Simon François Ravenet, an engraver from France who later moved to England and perfected the process he called "décalquer" (which means "to copy by tracing") it became widespread during the decal craze or mania of the late 19th century. The word is short for decalcomania, a decorative technique by which engravings and prints are transferred to pottery or other materials. A decal being attached to a piece of machineryĪ decal ( / ˈ d iː k æ l/, US also / d ɪ ˈ k æ l/, CAN / ˈ d ɛ k əl/) or transfer is a plastic, cloth, paper, or ceramic substrate that has printed on it a pattern or image that can be moved to another surface upon contact, usually with the aid of heat or water.

0 kommentar(er)

0 kommentar(er)